You probably know about the Carron Company ironworks, but this lesser-known story focuses on the popular baths that used to be made by the Carron Company, and are still produced by Carron Bathrooms today.

Initially, the traditional cast iron baths produced from 1866 were what Carron was known for.

fields['text']) echo $section->fields['text']; ?>

Today Carron Bathrooms only manufactures on a small section of the original Carron Ironworks site. While the Carronade and the Fire Grates are probably the products most associated with Carron, baths were also an integral part of the business. Initially, the traditional cast iron baths produced from 1866 were what Carron was known for. In 1965 they first began to manufacture acrylic baths. They are proud to continue in the footsteps of the giant that was the Carron Company.

The history of baths can be traced all the way back to the Great Exhibition of 1851 at Crystal Palace where a stylised, marbled luxury private bath was a showpiece displayed at the exhibit. Baths entered production at Carron fifteen years after the exhibition. The first style made by Carron had a ‘japanned’ finish.

The bathroom was not a widely recognised concept in the Victorian home. As such there was little demand for the bath products produced by Carron in the 19th Century. This was compounded by the fact that piped hot water was not readily available in most homes.

By the turn of the century, bath sales began to pick up and the Carron ironworks became one of the leading bath manufacturers in the United Kingdom. By the 1930s Carron also established its own bath manufacturing department at the works. Their 1939 advertising boasted: “What can be seen in a Carron bath? Not just a modern necessity of fine design, sound construction and good finish: there is more to be seen than that.” At one point in the mid-20th-century they even opened a bath plant in South Africa.

The Carron Works Documentary

At 7:30 pm on the 15th of November 1956, 8 million people tuned in to the BBC to watch a documentary on the Carron Works. The documentary had an initial focus on the Carronade, but it was the Carron bath that stole the show. The documentary was a result of painstaking research and attention to detail on the BBC’s behalf. Technicians from the BBC were at Carron for four weeks prior to the broadcast to ensure everything was in place for the documentary.

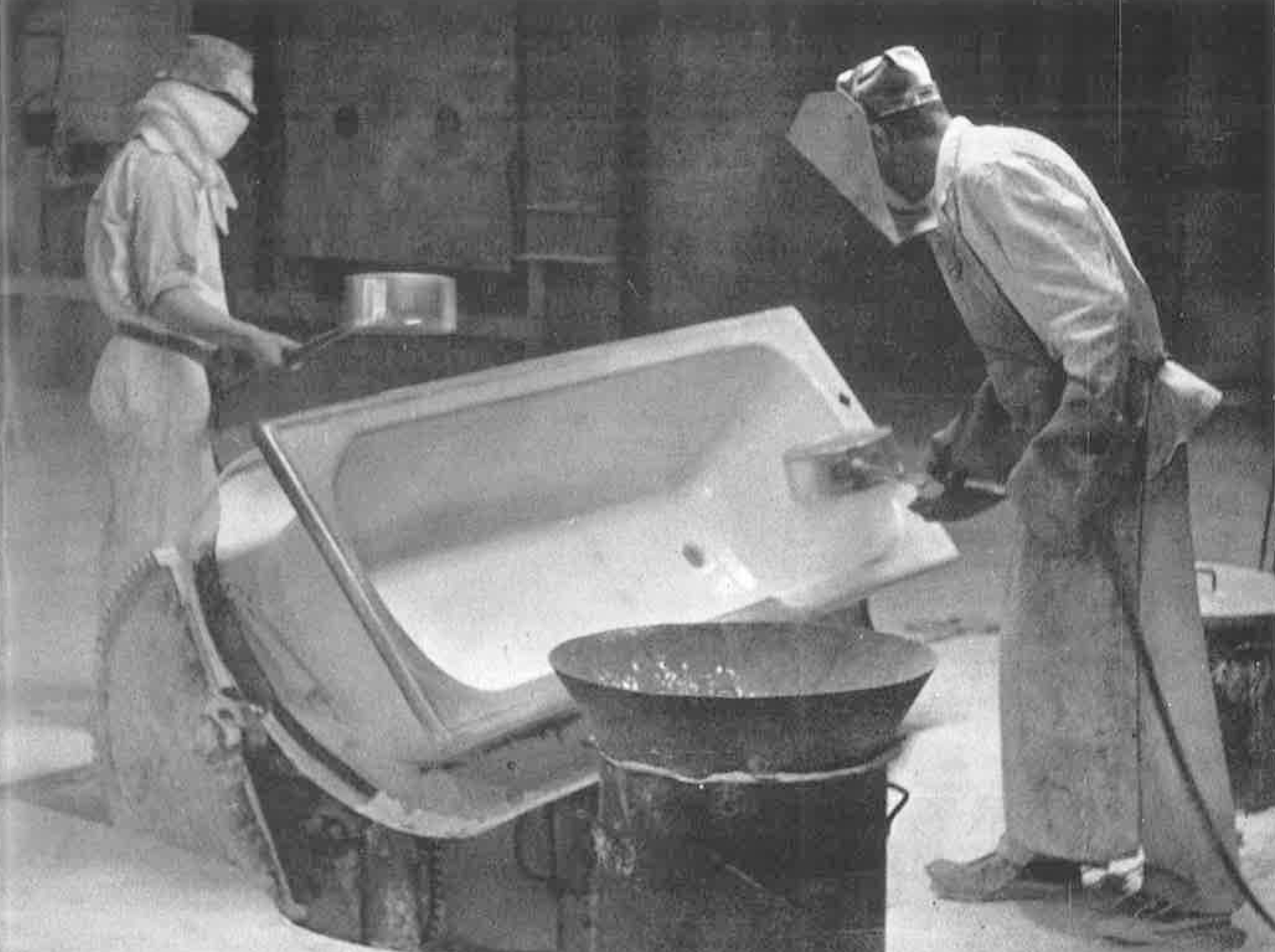

A key part of the documentary followed the bath manufacturing process. This process was very different from the way in which Carron baths are manufactured today as the baths at that time were cast iron and the process involved each bath being placed inside a blast furnace.

Viewers were fascinated by the stories of the people who put so much effort into making the baths. One story focused on a man who worked in the factory who, during his service in Greece in the First World War had come across a Carron bath, which he helped make. The documentary also told the story of the three Wright brothers, Andrew, John and James, who had worked at Carron for over 100 years combined.

The first major change in bath manufacturing at Carron came in 1965. In addition to the traditional cast iron, the company broadened its portfolio and expanded into acrylic baths. Over the course of the 1970s, the popularity of acrylic baths soared, while the Company also continued to manufacture steel baths with the Steelenye.

Carron Bathrooms

In 1982 the Carron Ironworks closed. Carron Phoenix and Carron Bathrooms have attempted to carry on the legacy of the Carron Company since the original company dissolved. This link to the past has been used to promote the brand and also forms the values that still guide Carron Bathrooms today. The importance of ‘conformance to specification’ in Carron lingo, otherwise known as the quality of the product, was key to the success of Carron bathrooms. As they said in 1939 “fine design, sound construction and good finish” are key qualities in a Carron bath. It is these principles that we continue to follow today to propel the business forward.

The workforce and community of Carron are what drives the achievements of Carron today, just as it probably did in yesteryear. It is no exaggeration to say that it is the hard work and dedication of our staff that is the company’s strongest assets. Carron Bathrooms aims to be the best company we can possibly be; a company respected by our customers, suppliers, competitors and by the community of Carron. To be a company for which our employees are proud to work.

By John Mcorrine.